2017 01 17 Engine Cradle

Remember You Can Click Pictures for a Larger Picture

It has been awhile since I have done an update under the dragster category. There actually has been a lot going on behind the scenes and I will have to do a couple of updates to get caught back up.

In this update we will talk about pulling the engine and transmission out of the dragster and building another engine cradle for the dragster engine. The old cradle is in Indianapolis with the new aftermarket block. That build is coming along and will be a subject of an upcoming update.

We have decided to freshen up the old engine that is in the dragster. There are a number of reasons. 1) I’m not sure I will have enough time to make the changes needed to put the new engine into the dragster, 2) We had just gotten comfortable with tuning the old engine to be able to “run it out” in an 8 second index, 3) It will allow us to move up another index to 7.5

When I say freshen the engine, what we will be doing is installing billet main caps and replace rods (if needed), valve springs and gaskets. The front cap will be upgraded along with the center three caps; the rear cap will not be upgraded. This means the block and caps will have to be line bored. The main reason for replacing the front cap will be to add strength in this area so that we can drive the blower harder. The center three billet caps will strengthen the block, to help from splitting the block down the center between the crank shaft and cam bearings.

Why do we need to drive the blower harder and strengthen the block? Well, we intend to run the 7.5 index with this block this season. We will need around 200 HP more than what we currently are running.

To help do that we will remove a fair amount of weight: radiator, coolant (water), water pump, expansion tank and hoses will be removed. The battery will be replaced with a light weight 16 volt battery. The 16 volt battery will be needed when we move to the new engine with a Mag. With the weight reduction we might only need a 150 more HP.

By moving to the 7.5 index, we will have more time between runs to cool the engine down. We will no longer have to run slower vehicles as the 7.5 class is a standalone class and this means no more staggered starts. And this is something I am really looking forward to. It will be a step towards the final goal of running with the big boys (Steven Walczak) in the 7.0 index. Running Steve has been on my bucket list for a while now. He is the one that infected me with this speed bug in the first place.

A car Nuts meeting was called to pull the engine, transmission and build the new cradle (I will end up with two cradles, so one of these cradles will end up being sold. Do you know anyone that wants a Pontiac engine cradle?).

Turnout was good; Mike King and his wife came all the way from Canada via Ken and Donna Long from Greece.

Turnout was good; Mike King and his wife came all the way from Canada via Ken and Donna Long from Greece.

I will be having another meeting of the CarNuts soon. I would like to get the Gasser into the garage to start work on it again. I would like to get some of the electrical work, the fuel system done, and the floor boards welded this winter.

Tom was ready to work as is normal for him. His nose was to the grindstone asking “what can I do next”.

Tom was ready to work as is normal for him. His nose was to the grindstone asking “what can I do next”.

He and his wife are headed out to warmer weather later this month and will be missed.

I did not start taking pictures right away and, with the whirlwind of activity, a lot came apart before I caught up. Without reference pictures, I wonder how I am going to get it back together.

I did not start taking pictures right away and, with the whirlwind of activity, a lot came apart before I caught up. Without reference pictures, I wonder how I am going to get it back together.

Out comes the transmission, the first piece that needs to be freshened up. The flex plate certification needs to be updated and it is cheaper just to buy a new one. The transmission is going to Indiana to Dan Dishon owner of Dishon Transmission

I had forgotten about this damage in the mid pl ate. This happened in the semi-final run in the Blue Suede Cruise at Norwalk when all the bolts holding the torque converter to the flex plate sheared. We went to six bolts from three after this happened and have not had a reoccurrence of this problem

ate. This happened in the semi-final run in the Blue Suede Cruise at Norwalk when all the bolts holding the torque converter to the flex plate sheared. We went to six bolts from three after this happened and have not had a reoccurrence of this problem

It is pretty light now. Too bad we need all that other stuff to make it go down the track.

With this weight reduction, I do not think we need additional HP to run the 8.0 index

Now that the engine is out, we need a place to put it and a way to transport it. Here is $32.00 in materials. I’ll make something to keep the engine secure.

Now that the engine is out, we need a place to put it and a way to transport it. Here is $32.00 in materials. I’ll make something to keep the engine secure.

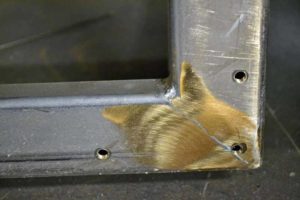

Mitered corners just like in a picture frame

Mitered corners just like in a picture frame

Starting to look like something. I used the scrap from the mitered corners to brace the uprights.

I had picked up some used casters that were going to be thrown out. This is a good place to use them. I drilled and tapped holes in the bottom of the cradle to screw in bolts to hold the casters in place.

I had picked up some used casters that were going to be thrown out. This is a good place to use them. I drilled and tapped holes in the bottom of the cradle to screw in bolts to hold the casters in place.

After sand blasting and grinding and then out-gassing the cradle in preparation for powder coat, this is what we have. Add some leftover powder from another project and it now looks pretty.

Final assembly

It is ready to hold the engine

After 490 miles and 10 hours of driving,  the engine is now at Freedom Racing Engines ready to be freshened up

the engine is now at Freedom Racing Engines ready to be freshened up

And it is in an impressive shop to have that happen.  It is supposed to be ready to put back into the dragster at the end of February

It is supposed to be ready to put back into the dragster at the end of February