2017 04 19 Prepare for Season Day 3

Remember You Can Click Pictures for a Larger Picture

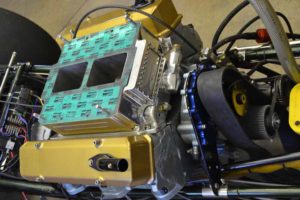

Progress continues on the dragster getting ready for the 2017 season.

Really starting to feel the pressure now, what we do not need is any set backs and that is just what we got. Read on.

So as a reminder, this is where we are: we are missing some major pieces.

This spacer is needed so that the distributor will fit under the rear edge of the blower and allow me to mount the burst panel so that it faces forward. It is really dirty and needs to be cleaned up, so it will be.

Next piece to go on is the blower. There is much controversy over what oil should be put into the blower. Even the Littlefield website is lacking in information. I called them and they said to put whatever you are running in the engine in the blower gear case. A very experienced drag racer suggested running the oil you mix into gas for a two cycle engine. He believes that is a good oil to run in case a seal goes. The engine will burn the oil rather than detonate and hurt parts. It is very difficult to see oil in the site glass. Littlefield said to pull the snout bolt at 7 o’clock and oil should run out if you have the right amount of oil in the gear case. It appears that I do.

Need to keep adding parts, so next is the gasket and then the blower. We are making progress, but wait I promised a setback and it is coming.

Time to polish some more parts, and add them to the collection. I had already polished the expansion tank before I thought to take a picture, but it was in the same condition as the mounting bracket that is beside the tanks.

Time to polish some more parts, and add them to the collection. I had already polished the expansion tank before I thought to take a picture, but it was in the same condition as the mounting bracket that is beside the tanks.

Uh Oh, I spotted this gasket. It is the gasket between the valley pan and the block. I do not use a gasket here just for this reason. I had had the engine out at a shop as we added billet main caps and that shop put the valley pan on with a gasket. Now everything needs to come back off to fix this problem.

Off everything comes, including

the  valve covers. What a bummer and it puts me behind the 8-ball

valve covers. What a bummer and it puts me behind the 8-ball

Turns out the valley pan gasket was not stuck to the valley pan. There was sealer on the valley pan, but the gasket must have had oil on it or something as it pealed right off without doing any damage to the gasket. The left corner of the intake gasket was the same way so it had to come off also.

It turned out I needed to remove the  right intake gasket as well as it interfered with placing the valley pan back onto the block. When I wiped down the valley pan before putting the sealer on I got quite a bit of oil, see the green rag.

right intake gasket as well as it interfered with placing the valley pan back onto the block. When I wiped down the valley pan before putting the sealer on I got quite a bit of oil, see the green rag.

I used Permatex Ultra black because it provides maximum oil resistance, is for Heavy Duty oil applications and is ideal maximum gap applications. I do not use a gasket here as I have had problems before with them squeezing out. I was really happy with the bead that squeezed out when I tightened down the hold down bolts on the valley pan. Not too much and not too little. I have yet to find an aftermarket valley pan that fits correctly. Note how the pan is short in the foreground and too long in the background.

So now it all goes back together again.  Lost at least a day here. We have a long way to go.

Lost at least a day here. We have a long way to go.