2010 Front Engine Dragster Week 2010 12 27

REMEMBER TO CLICK PICTURES FOR MORE DETAIL / LARGER PICTURE

It has been awhile since I produced an update. I’m going to jump ahead to 12/27/2010 and start there. The painting has been finished and the dragster has been picked up from Indiana and brought home.

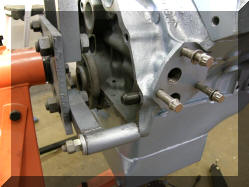

The engine, transmission and engine plate were pulled from the dragster.

I have a Doctor appointment in the morning at 10:30. Later in the day I hope to test fit the flex plate on the rear of the engine and bolt the starter in place. This will allow me to check the gage between the starter gear drive and flex plate and adjust as needed.

If that goes well I will try and get the engine back between the rails.

It was discovered in this process that the drive shaft was missing, but Roo Man is shipping it.

Once the engine is in place I will return to wiring.